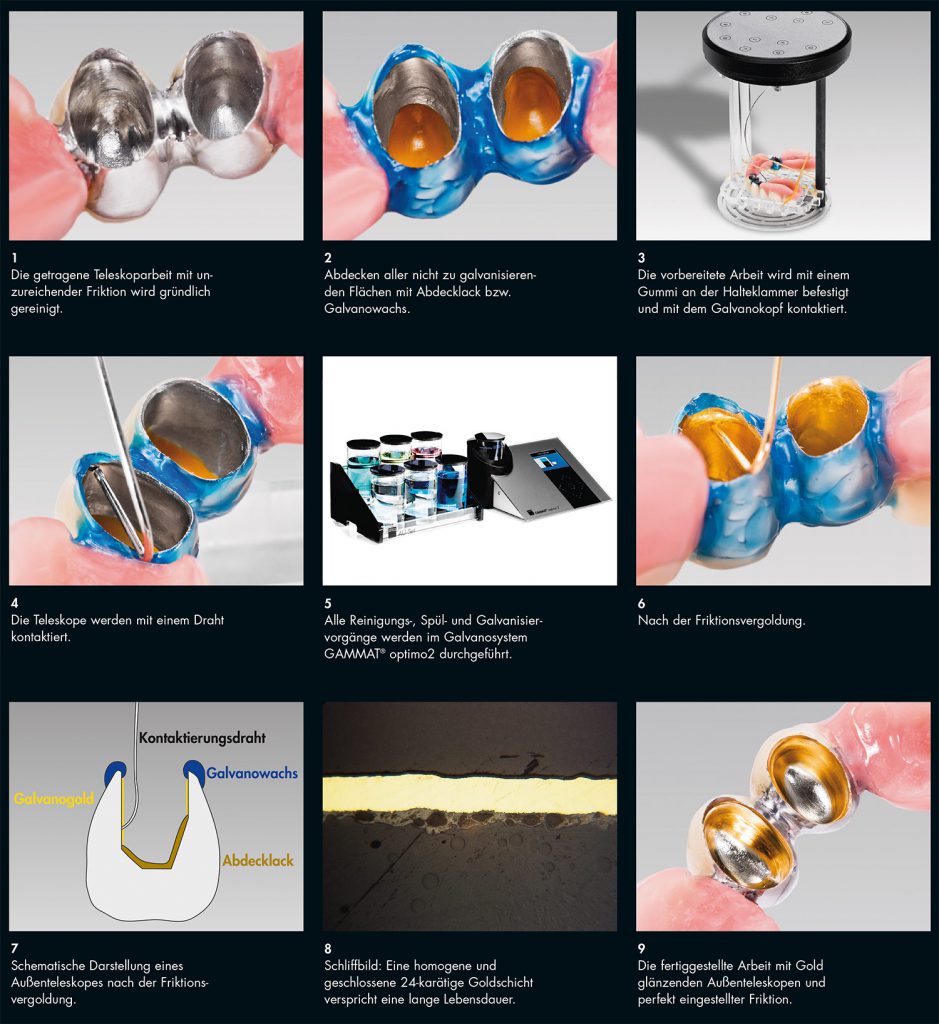

Friktionserneuerungen von getragenen teleskopierenden Arbeiten – präzise, funktionell und erprobt

Problematik

Welcher Zahnarzt kennt die Problematik nicht: Eine teleskopierende Arbeit, für die der Patient womöglich noch viel Geld aus eigener Tasche investierte, zeigt nach einiger Tragezeit nicht mehr die gewünschte Friktion. Doch welche Möglichkeiten stehen zur Verfügung, um eine schnelle und vor allem dem hochwertigen Zahnersatz angepasste Reparatur zu ermöglichen, die zudem noch für den Patienten erschwinglich ist?

Realisierung

Die eleganteste Methode der Wiederherstellung der Friktion besteht mit Sicherheit in der galvanischen Abscheidung von Material in das Außenteleskop. Hierfür nutzt das GAMMAT® optimo2-System die Vorteile des Galvanoforming: Durch die sensorgesteuerte Abscheidung und die einzigartige Hydrodynamik ist ein homogener Schichtaufbau gewährleistet. Durch eine nur wenige zehntel Mikrometer starke Vorvergoldungsschicht wird ein sicherer Haftverbund zwischen der Gusslegierung des Außenteleskopes und des 24-karätigen Goldes der Friktionsschicht erzielt. Der Auftrag der zirkulären Goldschicht im Außenteleskop erfolgt in einem Galvanisierprozess, dessen Zeit abhängig von der Menge der Teleskope und der aufzugalvanisierenden Schichtstärke ist. Diese kann 5, 10 oder 15 µm stark sein. Durch die Gleichmäßigkeit der aufgetragenen Goldschicht laufen die Teleskope wieder weich – eine funktionierende Friktion ist wieder hergestellt. Gering ist die hierfür benötigte Menge an Galvanogold, was die Kosten in Grenzen hält. Wenn möglich sollte der Patient während der Anfertigung der Friktionsvergoldung zur Kontrolle im Labor anwesend sein.

Fazit

Schlussendlich kann man sagen, dass die von Gramm Technik entwickelte Methode der Friktionserneuerung mit Abstand die eleganteste ist. Denn hier wird nicht nur hochwertiges Material verwendet, sondern sie verspricht auch einen gezielten Goldauftrag, der es erlaubt, den Begriff Friktion überhaupt zu benutzen – bei den meisten Systemen kann eher von einem Verkanten bzw. Verspannen gesprochen werden. Außerdem liegen inzwischen über 15 Jahre praktische Erfahrung vor, die ein durchweg positives Ergebnis und eine günstige Haltbarkeitsprognose zulassen.